Self-landing rockets, self-driving cars, and a Guinness world record of 1,300 self-dancing robots–Ok, that may not be a huge deal–but 2018 is the year of autonomy. The machines have finally taken over and this is a good thing! Now more than ever we have new opportunities for innovation in transportation which will further advance the world of architecture, construction, and land development. Autonomous may as well be synonymous with cost-effective, not just for your money’s sake, but your time as well. One of the minor, but ever-prominent troubles of life is never being able to find a parking spot for your car, so why not bow to our new robot overlords and let them park it for you?

Watch as Robert races an automated parking garage to see how you can save time on your driving commute.

I first learned about autonomy in high school while participating in the FIRST ROBOTICS organization. Students learned how to program their robots, which they make from scratch under the guidance of mentors, in order to complete a task that usually involves moving large, cumbersome objects. The purpose, of course, is to win a game against other competing schools, but moreover, it’s to spur innovation into the young minds of our future engineers and programmers. Machinery that completes difficult, often awkward labor for mankind has been around for centuries. If you’re skeptical, ask anyone who owns a sewing machine. It’s been around since 1846. But now we are putting robots to the test to make our world less hands-on and more mind-on. The phrase, “work smart, not hard,” rings true now more than ever.

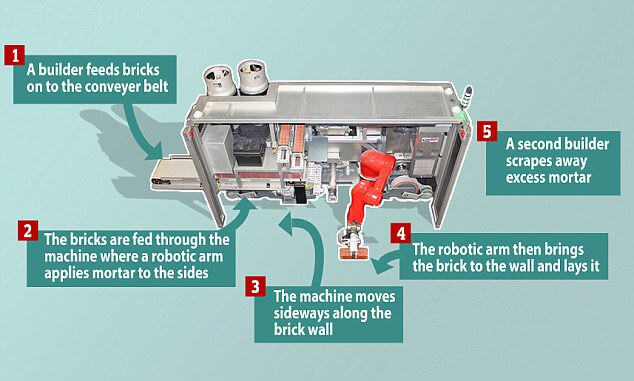

Say hello to SAM.

Image: www.phillytrib.com/news/bricklayer-contest-muscle-sweat-fend-off-future-rival-sam

Unless you’re keen on staying current with construction news, SAM (Semi-Automated Mason) has probably been under your radar. It’s been around since 2015 and has been increasing productivity on job sites like a textbook example employee of the month. SAM can lay 3,000 bricks per day, whereas you or I would typically lay 500 bricks on a good day. But just because SAM is clearly faster at laying bricks, that doesn’t mean it’s putting construction workers out of a job. In order for SAM to be a good employee, it needs assistance from at least two fellow bricklayers and does have issues with rounding corners, according to a rep from an interview with the New York Post.

Image: www.dailymail.co.uk/sciencetech/article-4352794

SAM has had updates since its debut and is more than likely only going to improve over time. However, one thing SAM can’t do is build you a home in 24 hours. A whole house was built in 24 hours using a 3D printer–yes–the same thing that can make limbs for people is now building 400-square foot homes.

A 3D printer can print out concrete walls and partitions for a small price. That’s only for the shell of the building though. This machine can’t install a roof, insulation, wires for electricity, or a water heater. A true home still needs a human touch to make it comfortably livable. The true cost isn’t technically $4,000. With the added cost of everything described above and human builders, a 3D printed home can cost over $10,000, according to a similar project in Russia. Structures at a relatively low cost, not including the land they would occupy, can be a tremendous asset to low-income housing, or small retail shops and farmer’s markets.

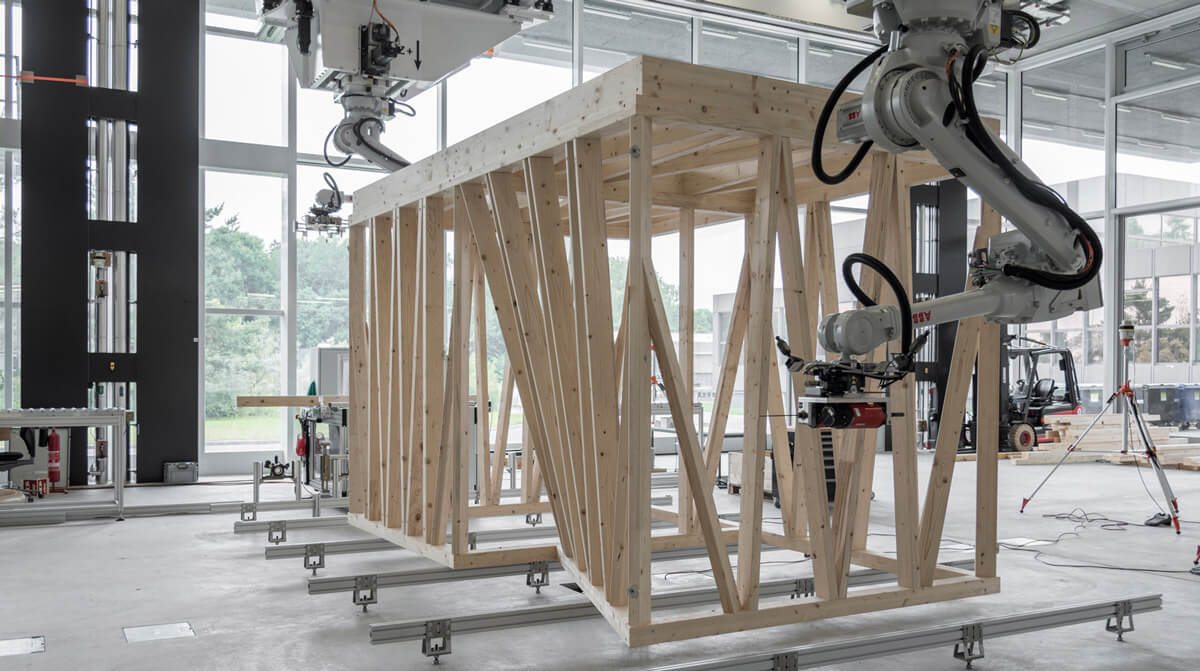

Undeniably, the increases in efficiency and project completion from robotics and software on all levels of architecture and design are a welcomed addition to the profession, but we are still far away from being a fully autonomous world. Just because architects stopped drawing buildings by hand and switched to CAD as an industry standard didn’t mean we had fewer architects in the world. Instead, we gained those willing to adapt and use the latest tools in order to create the best home, bridge, and the humble parking garage.